How To Make A Fireless Cooker

By Kenneth Coggeshall

Taken From: Popular Mechanics Shop Notes © 1921

A fireless cooker is a device so constructed that, through the agency of insulating materials, accumulated heat may be retained. Just as the walls of a refrigerator insulate ice from any heat outside the box, so a (ireless cooker prevents heat radiation from its interior compartments to the relatively cooler surrounding air. Food, therefore, may be brought to cooking temperature, removed from the source of heat supply, and placed in a fireless cooker, where the process of cooking will continue.

The construction of such a cooker is not complicated; no special tools, skill, or materials are required. And, because of its many advantages over stove cooking, every kitchen should contain a cooker as a part of its necessary equipment. Its use will accomplish a material saving in fuel, decrease the time and labor of cooking, and eliminate heat and odors from the kitchen, and besides provide thoroughly cooked, fully flavored foods. The requisite parts for such a device are a box; a bucket or kettle for holding the food; a container, or other metal nest lining, for the bucket, and a quantity of good nonconducting or heat-insulating material.

While the outside container may be made from any tightly constructed box. half barrel, or small trunk, a chest built for the purpose will not only present a more pleasing appearance, but will be more economical of space. One-inch cypress boards, free from all knots and other defects, should be used. Cypress, if properly finished, will give beautiful grain effects, and is less expensive than hard woods. Lighter lumber should not be considered unless well braced; the pressure exerted in tamping in the insulating material is likely to bend out of shape the boards of the box, if they are thinner than the weight specified.

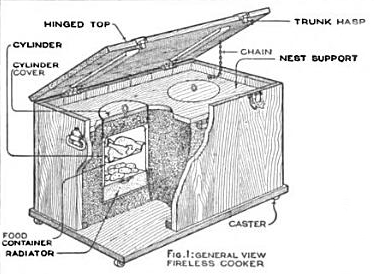

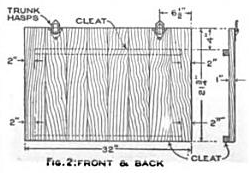

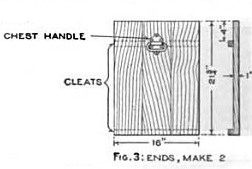

The general appearance of the chest is shown in Fig. I. The front and back are matched and fastened to cleats or cross-pieces, as indicated in Fig. 2. Two end sections, seen in Fig. 3, are constructed similarly. Cross cleats are also utilized here, at both top and bottom, to hold the boards in position.

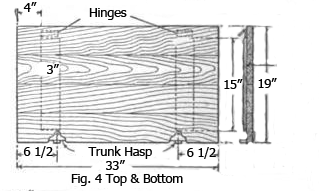

While the top and bottom sections, shown in Fig. 4, are identical as to dimensions, they may be different as to finish. It is permissible to use rough, unfinished lumber for the bottom; the top should be constructed of selected cypress to match the sides and front of the chest. Moreover, since both sides of the top are presented to view, the workmanship should be of the best.

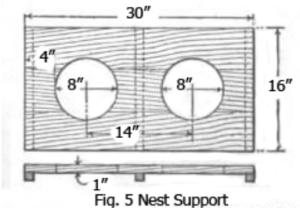

The sides, front, and back should be first assembled, leaving the cover and bottom unlit later. Two inches from the top edge of the chest, a wooden nest support should be fastened in position. This support is constructed as shown in Fig. 5. Using a keyhole or band saw. cut two 8-in. holes, at the positions indicated.

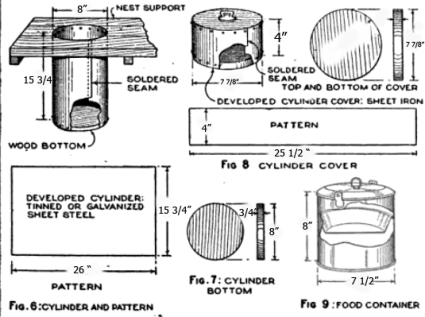

The metal cylinder lining, illustrated in Fig. 6. is cut from sheet line or galvanized iron: it is rolled into a cylinder, and the seam soldered. For a cylinder of this size, the developed dimensions of the flat metal will be as given in the pattern. It may be found possible to use heavy cardboard instead of sheet iron, but the latter is more durable and far more sanitary. Two such cylinders are required.

Prepare two wooden disks, detailed in Fig. 7, to serve as bottoms for the cylinders. Fasten them in place, as shown in Fig. 6, with small nails. The free ends of the cylinders are then fitted in the 8-in. boles in the wooden support, and fastened with screws or nails. The nests being thus prepared, the insulation may be packed in place.

Practically any material which will not conduct heat may be used as a packing. Mineral wool is perhaps the best, since it is fireproof, sanitary, and odorless. It is recommended for the cooker here described. Asbestos is also fireproof, and may be used with success. Ground cork, such as Is used in packing grapes, is excellent, and can probably be obtained from a fruit dealer. Other suitable insulation are Spanish moss, excelsior, cotton, crumpled paper, hay, and even hard coal cylinders. If fireproof insulation cannot be obtained. Asbestos should be wrapped around the outside of each metal cylinder.

With the chest upside down and the bottom removed, carefully pack in the insulating material. Every crevice, especially near the metal cylinders, must be tightly tamped full of the packing. Fill up, as far as possible, all air spaces which might cause heat convection. When the insulation fills the chest to the level of the edges, screw or nail the bottom section in place.

The top should now be attached, the hinges being placed at the back. A light chain may be used to prevent the top from falling backward. Two chest fasteners, secured at the points indicated in Fig. 2, may be utilized to hold the top tightly closed when the cooker is in use. A handle on each end of the chest will improve its appearance as well as aid in moving the cooker about. Easy-running casters should be provided, one at each of the bottom corners. Stain, oil, or varnish may be used to complete the finished surface of the chest.

The construction of the insulating cover, seen in Fig. 8. requires some degree of skill in matching the 8-in. holes in the nest support. Two metal cylinders are formed, of dimensions given. Two wooden disks, as detailed, are required for each cushion. Fasten one of these disks in place as a bottom to the cylinder, the container thus formed with the insulating substance, and attach the top wooden disk. After an addition of a wire handle, or a knob, in the upper disk, the assembled cushion appears as in the first view, Fig. 8.

Needless to say. the kettles or containers for cooking should be durable, and as free as possible from scams. Perpendicular sides are necessary to insure a tight fit in the nest. Obviously the container covers should also fit closely, to prevent the escape of steam. While it is possible to purchase utensils for use in fireless cookers, a bucket serves the purpose just as well. The cooker here described is designed to use two standard 6-qt. buckets. Larger containers may, of course, be substituted, provided at least 4 in. of insulating packing surrounds them. While tinned ware can he used, experience shows it will rust after but short use. Enamelware, or better still, aluminum, insures longer service; a suitable container is illustrated in Fig. 9. If the handle is in the way, remove it, and provide two metal hooks for lifting the bucket out of the nest, similar to the one mentioned below for lifting the radiator.

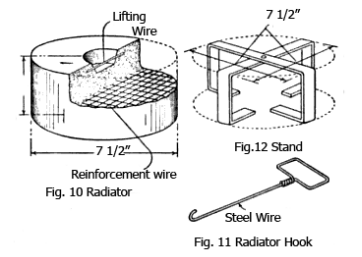

It is not always necessary, as experience will prove, to furnish additional heat to assist the process of cooking. A much wider range of cooking, however, is provided if an extra source of heat supply is available. Soapstone radiators may be purchased for fireless-cooker use, but a brick, or iron disk, such as a stove lid. proves just as efficient. A radiator to match the dimensions of each cooker is easily made of cement. Molds, similar to the cover cushions, should be provided. It is not necessary that the radiator be larger than 7½ in. in diameter, and 3 in. in height. For reinforcement, a disk cut from heavy wire mesh, such as in Fig. 10. is employed. After the cement is poured in the mold, it must be placed in some location where it will dry slowly to avoid cracking. Besides the reinforcement, it is best to provide a lifting wire by forming a depression, exposing the middle pan of a heavy wire imbedded in the cement. The radiator can then be lifted by griping this wire with the hook shown in Fig. 11. The initial warming of the radiators should not be accomplished in haste. This caution also applies to the use of purchased soaps tones. Unless these stone radiators are stored in a warm, dry place, they will crack when heated on the stove. Two iron stove lids of the correct size, bolted together, make a much more durable radiator and one that may be heated to a high degree.

Other accessories may be provided as required. A stand, for instance, such as is shown in Fig. 12, is convenient when two pies or cakes are being baked in one compartment. This stand is made of light strap iron, formed as indicated. Fans can be placed both inside and on top of it.

Figs. 1 and 9 also present a method of placing a pan inside one of the buckets.

Food may thus be cooked in the bottom space while its retained heat assists in the cooking of the contents in the pan above. Three angle lugs are riveted to the side of the bucket to form the pan support.

By referring to the sectional view of Fig. 1, the method of placing the various parts in the nest may be seen. A small dead-air space is permissible between the vessel and the cylinder walls, as circulation of air inside the cylinder cannot carry heat to the outside.

A fireless cooker can be utilized to greatest advantage in preparing foods which require long boiling, stewing, or steaming. Such foods are soups, cereals, meats, steamed bread or pudding, and vegetables. Obviously, large quantities of food, because the accumulated heat is greater, will cook faster and more thoroughly. If it is necessary to prepare a comparatively small quantity of food, good results are obtained by putting it in some container similar to a baking-powder can or a l- quart bucket, which should then be placed in the 6-qt. bucket, after pouring into the latter a suitable quantity of boiling water. The radiators, previously healed to a high degree on the stove, will assist in preserving a cooking temperature in the nest compartment.