Kerosene Lamp

Taken From: Equipment For The Farm And The Farmstead

By Harry C. Ramsower © 1917

Although kerosene had been known and, in a limited way, used for purposes of illumination for several centuries, it was not until 1859, when Drake made his petroleum discoveries in Pennsylvania, that it became a commercial possibility. In that year the first American patent for a petroleum lamp was granted; before the year was ended forty other applications had been presented, and for the following twenty years eighty applications a year were made, on an average.

Crude petroleum is a liquid varying in color from pale yellow to black, and has a disagreeable odor. Its specific gravity ranges from 0.8 to 0.9. It is made up chiefly of carbon and hydrogen, being on an average about 8 5 per cent carbon and 1 5 per cent hydrogen. It is composed of a variety of the so-called " hydrocarbon " compounds, which are separated the one from the other by means of fractional distillation. On being subjected to heat, naturally the lighter and more volatile compounds pass off first. Among the first of the distillates to pass off is gasoline, with a density of about 0.65, followed by the naphthas .(including benzine), with a density of 0.68 to 0.74, and kerosene, with a density varying from 0.78 to 0.84. These lighter compounds are then followed by the various grades of lubricating-oils, with densities from 0.87 to 0.93, after which come the heavier oils, or greases, as vaseline.

Kerosene should be nearly colorless (though it sometimes approaches a yellow color), and it should not give off inflammable vapor below 120 ° F. It is much better if inflammable vapors are not given off below 150 ° F., since frequent lamp explosions are due to the fact that the heat of the flame causes the oil in the fount to vaporize, a condition which, if the wick-holder is taken off or the filling-cap removed, is likely to result in the explosion of the vapor.

The kerosene lamp in its typical form consists of the bowl, or fount for carrying the oil, the wick-holder, the wick, and the chimney.

The wick-holder, or burner, consists of a device for raising or lowering the wick, of a perforated platform, or gallery, which supports the chimney, and of the dome which surrounds the upper portion of the wick. The perforations in the platform of the burner are for the purpose of breaking up air currents in order that the air may be evenly distributed as it passes up around the flame. The dome assists in directing the air currents against the flame at the points where the most air is required, and steadies the flame.

The operation of the lamp may be explained as follows : by the force of capillary attraction the oil is drawn up through the wick to the flame, where it is volatilized by the heat of the flame, and where the carbon and the hydrogen of the oil vapor, uniting with the oxygen of the air, yield carbon dioxide and water, the usual products of combustion. The luminosity of the flame is due to the fact that, since some of the carbon is not completely consumed, the free carbon particles floating about in the flame are heated to incandescence.

Just the proper amount of oil must be supplied not too much and not too little. If there is an excess of oil, or, rather, a deficiency in the air supply, products of incomplete combustion will result, such as carbon monoxide and petroleum vapor - the former injurious to the health, even poisonous, in fact, and the latter very disagreeable. These conditions will also result in the deposit of carbon, or soot.

To control these two factors, the oil and the air, the fount must be kept well filled with oil, and the wick must not be allowed to become too short. There is a tendency to use a wick as long as it touches the oil, but a wick just dipping into the oil will not feed freely – it should extend well down to the bottom of the fount. Some authorities claim that a new wick should trail the bottom at least two inches and should be discarded when the trail is used up; the statement is perhaps true for maximum efficiency. The wick should not be unduly compressed in the wick-holder, as this tends to break the capillarity. The air supply is frequently interfered with if the gallery perforations become clogged.

There are several types of kerosene lamps, the types differing mainly in the construction of the burner and the wick. The principle of operation as explained above applies to nearly all types, though there are slight differences arising from construction details which will be pointed out in the following paragraphs.

The flat-wick lamp. This was the first form of kerosene lamp to come into prominent use. There is a wide variation as to size and shape of fount and width of wick. The latter varies from ½ in. to 1 ½ in. in width. This type of lamp when supplied with a wick 1 ½ in. wide will develop about 12 candle power and will burn from fifty to sixty hours on 1 gal. of fuel.

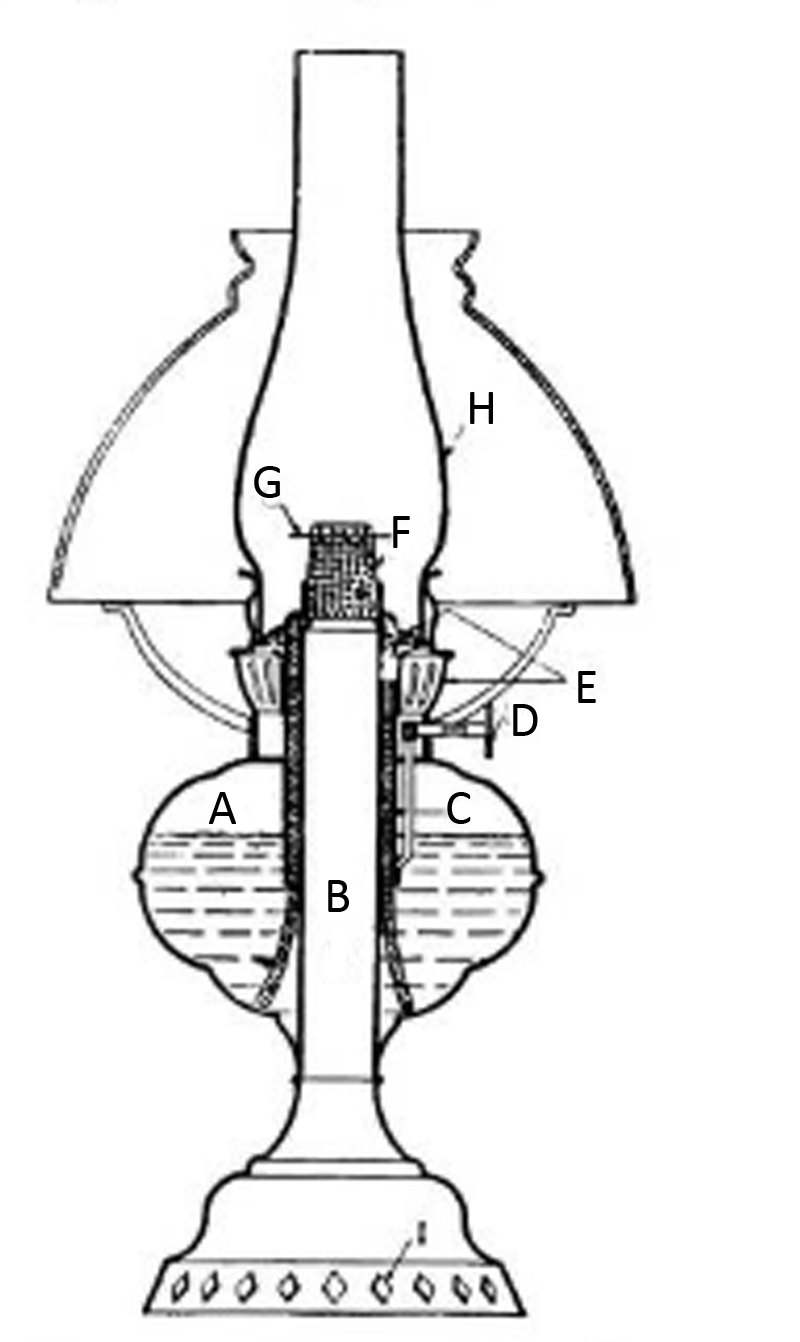

The round-wick lamp. The round-wick kerosene lamp was the result of an effort to secure a more even distribution of air around the flame, thus bringing about more complete combustion. The principle of this type of lamp is illustrated in the cross section shown in Fig. 71. The central draft- tube extends from the base of the lamp to the top of the burner. The flame is thus supplied with air from both sides. The flame-spreader diverts the flame from the vertical path which it would naturally take in following the draft currents.

This type of burner is generally known as an Argand burner, from the name of its inventor. A lamp equipped with such a burner 1 ½ in. in diameter will develop about 18 candle power and will burn from twenty-five to thirty hours on 1 gal. of fuel. Its efficiency is not greatly superior to the flat-wick lamp, its increased candle power being chiefly due to the increased wick surface.

The mantle lamp. Fig. 72 shows a kerosene mantle lamp. This is a lamp of the round-wick type, with a mantle suspended above the flame. Its construction and operation are essentially the same as the round-wick lamp, though for highest efficiency it requires greater care in its manipulation.

A. Fount

B. Draft Tube

C. Wick

D. Device to raise and lower the wick

E. Gallery

F. Dome

G. Flame-spreader

H. Chimney

I. Air Vents

The mantle is responsible for the higher efficiency of the lamp and is at the same time the source of the difficulty encountered in the actual use of the lamp. The mantle is made of a small cylinder of cotton net soaked in a solution of the nitrates of some of the rare earths (chiefly thoria and ceria), after which the net is burned. During the process of burning, the nitrates are changed to oxides, only the framework of the net remaining. This is then soaked in collodion (guncotton in ether and castor oil), to give a firm set to the structure. This material is burned off when the mantle is put in place on the lamp. The materials of which the mantle is made reach a high degree of incandescence when properly heated, and the lamp in consequence yields an unusually soft and pleasing white light.

The difficulty in the operation of a kerosene lamp equipped with a mantle comes from the fact that the mantle must be heated to a high degree, and, to attain the proper temperature, the fuel must be burned with a blue flame; that is, combustion must be complete, so that no carbon particles, or soot, will be deposited upon the mantle. This requires careful trimming and regulation of the wick. A special wick-trimmer is usually furnished with the lamp, and this should be regularly and carefully used. No attempt should be made to trim the wick with scissors or with a match stem, as is sometimes done. If the wick becomes uneven or if a thread is loosened and not cut off, the flame will be uneven and soot will collect on the mantle. Only the charred portion of the wick should be removed, and the trimming should cease just before the unburned part of the wick is reached.

When the lamp is lighted the wick should not be turned high. As the flame becomes even and the burner heats through, the wick should be gradually turned up until the full brilliancy of the flame is reached. This is an important matter, and its neglect often leads users of this lamp to become dissatisfied with it, when the fault is all their own. Should any portion of the mantle become coated with soot, it is only necessary to turn the wick down a little, when the soot will disappear.

Fig. 72. A kerosene mantle lamp

A shade, not shown here, is ordinarily used with this lamp

The mantle costs 25 cents and with reasonable care will last from two to five months. Many times it will last a full year. If the lamp is carried about from one room to another, it must be set down with care or the mantle will be jarred from its support.

The wick is supported in a special framework, and when it is burned short a new wick and frame should be supplied. No attempt should be made to put a new wick into the old frame, because it is impossible to get the wick perfectly even.

The best makes of mantle lamps cost about $6. They will develop from 50 to 60 candle power, and by numerous tests on at least one make it has been shown that they may be expected to burn about fifty hours on 1 gal. of fuel.

The quality of the light is of the very best. It's clear, white, soft rays are unusually pleasing, and when it is placed beside the common round-wick lamp the contrast between the white light of the former and the yellow light of the latter is very great. Attention will be called later to the healthful qualities of this lamp in comparison with other forms of illumination.